Technologies

10 substitutable automated production lines

At our plant, you have a total of 10 automated lines available that can each replace the others:

- 5 slitting lines for processing steel coils, outputting coils and strips with thicknesses of 0.4 mm and up and widths from 30 mm to 1650 mm,

- 5 cut-to-length and combined lines that produce rectangular and trapezoidal sheets with thicknesses ranging from 0.4 to 6.0 mm, widths from 100 mm to 1850 mm and lengths from 300 mm to 6000 mm.

We respond flexibly to market changes

- The majority of our production lines can serve interchangeably – this lets us react flexibly to unexpected situations.

- Thanks to our 30+ years of experience in the field and our high-quality technical infrastructure, we can produce a very wide spectrum of steel coils, strips and sheets.

- Our heated storage spaces with a total capacity of 40,000 tonnes enable flexible production.

- Thanks to our cranes with high load limits, we can easily handle goods with weights of up to 30 tonnes.

- We also have our own railway sidings, letting us unload wagons directly within our halls, increasing the efficiency of our logistics.

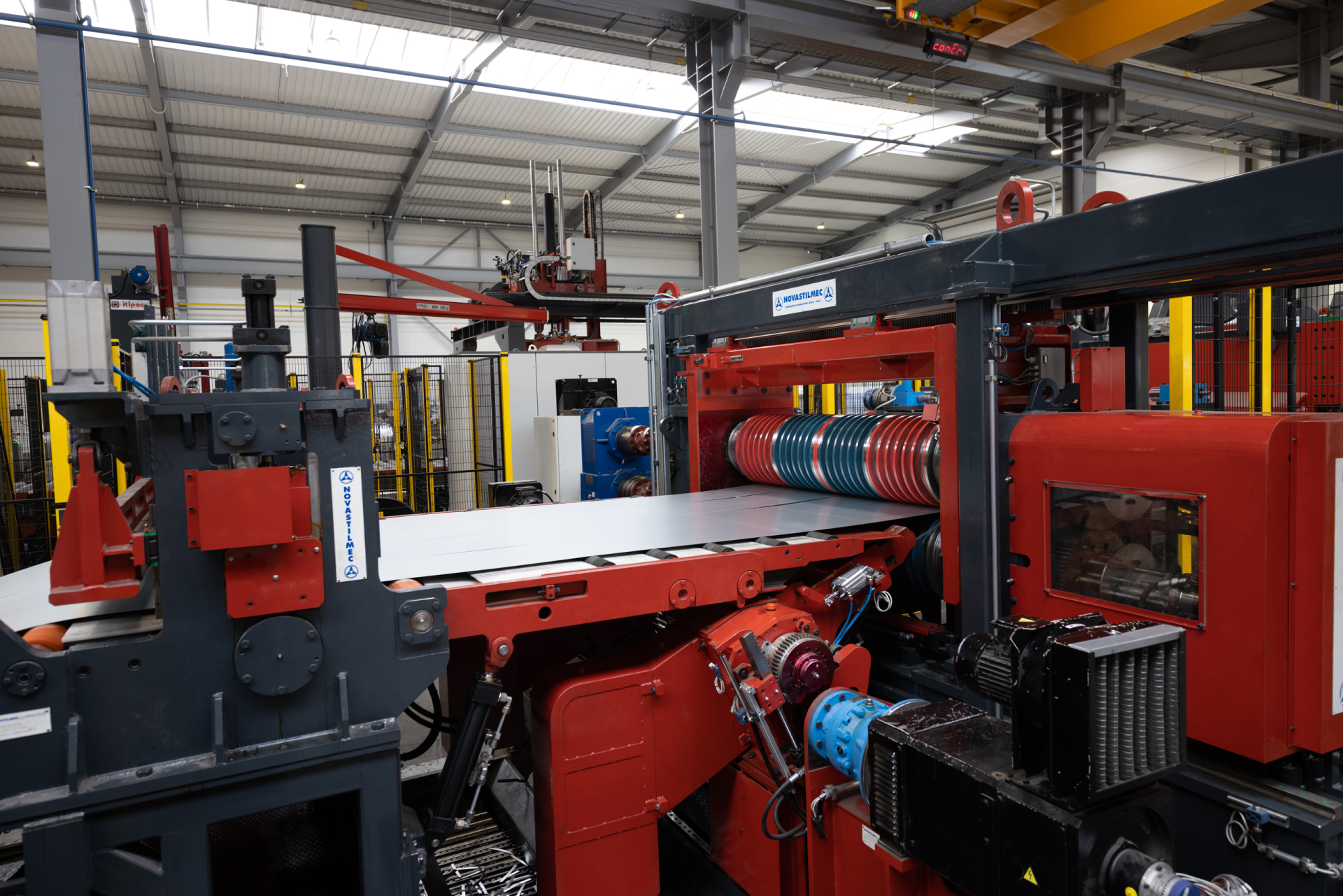

Selected ROSSO production lines

Slitting and packaging line in Zaječí

- magnetic tilting and stacking line,

- specialised in cutting ultra high strength steel with strength of up to 1,200 MPa,

- access to fully configurable equipment for oiling of coils,

- produces steel coils with a thickness range from 0.4 mm to 4.0 mm and strips with widths from 25 mm to 1,650 mm,

- works at speeds of up to 300 m per minute.

Slitting and packaging line in Mirošov

- magnetic tilting and stacking line,

- specialised in large input coils with weights of up to 30 tonnes and external diameters of up to 2,200 mm,

- equipped with an automatic strapping head,

- has a capacity of 15,000–20,000 tonnes a month,

- produces steel coils with a thickness range from 0.4 mm to 4.0 mm and strips with widths from 30 mm to 1,650 mm,

- works at speeds of up to 300 m per minute.

Cut-to-length line in Mirošov

- specialised in trapezoidal sheets and blanks,

- offers continuous operation and has highly adjustable levelling rollers, ensuring perfect flatness of sheets,

- produces steel coils with a thickness range from 0.4 mm to 2,5 mm and strips with widths from 100 mm to 1650 mm and lengths from 300 mm to 3,000 mm,

- is equipped with a magnetic storage device.

and 7 other production lines.

Need some advice?

Let us know. We’ll be glad to help.